Buna-N (NBR): What is it and When to Use it

Buna-N (NBR): What is it and When to Use it

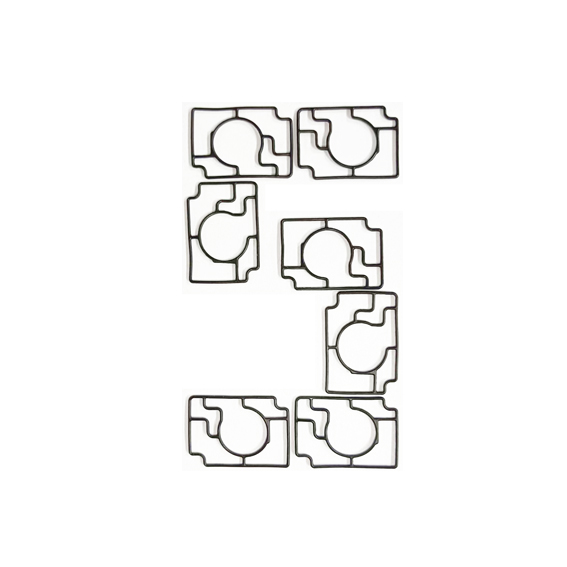

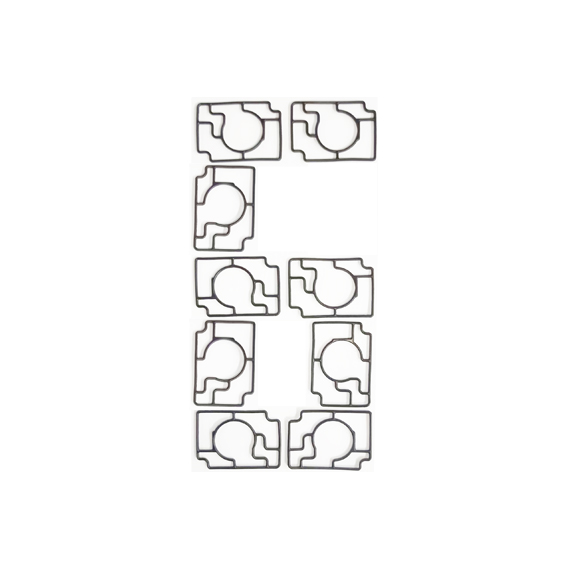

The Specials of Buna-N(NBR)

The Specials of Buna-N(NBR)

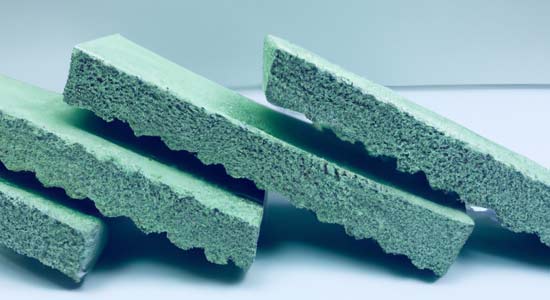

Buna-N, also called nitrile butadiene rubber, nitrile rubber, or NBR, is one of SUNLED's most popular materials. We call it our workhorse because it is dependable, hardworking, and cost-effective. It is also highly customizable and with the right mix-ins can be used for many different applications from gas and oil systems, footwear, and even clean water systems.

Because NBR is such a versatile and widely used material, it is important to understand its properties and when it is the optimal choice for sealing applications.

What is Buna-N (NBR)?

What is Buna-N (NBR)?

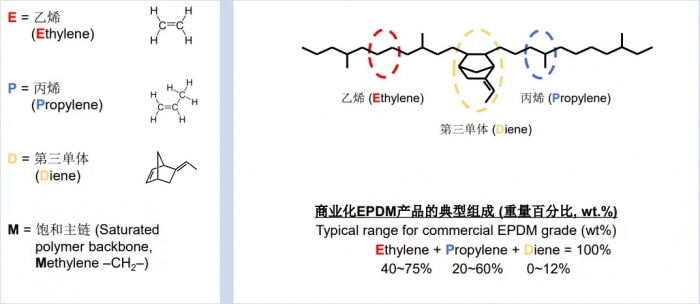

Buna-N is a synthetic copolymer made of acrylonitrile and butadiene. It is generally composed of 34% acrylonitrile, but the amount of this compound can range from 18%-50%. The more acrylonitrile, the more resistant Buna-N is to temperature and other materials.

Buna-N is known for its unusually high resistance to oils, fuels, and other chemicals and for its superior strength. It’s often found in automotive, marine, and aeronautical fuel and oil systems, disposable non-latex gloves, belts, hoses, o-rings, gaskets, oil seals, adhesives, footwear, and floormats.

Depending on its intended use, Buna-N can be customized with different mix-ins and accelerators. For example, Buna-N can be adjusted to ensure compliance with EN549, the European standard for rubber materials for seals and diaphragms for gas appliances and gas equipment. Alternatively, different adjustments can ensure Buna-N is safe for use with drinking water. Buna-N can be customized in infinitely different ways depending on its use and any specific standards it needs to adhere to. It can also be cured with sulfur or peroxide, which affects its temperature, hardness, and compression properties.

Buna-N (NBR) Rubber properties:

Buna-N (NBR) Rubber properties:

| Temperature resistance for Standard Compound | -40°C (-40°F) to 100°C (212°F) |

| Temperature resistance for Special Compound | -55°C (-67°F) to 135°C (275°F) |

| Hardness | 40 to 90 Shore A |

| ASTM D1418 Designation | NBR |

| ASTM D2000 Designation | BF, BG, BK, CH |

| Standard Color for shelf items | Black |

Pros of Buna-N

Pros of Buna-N

There are many advantages to working with Buna-N. It performs especially well in petroleum-based fuels and oils, aliphatic hydrocarbons, vegetable oils, silicone oils and grease, ethylene glycol, dilute acids, and water below 100°C (212°F). It also offers excellent abrasion and tear resistance, high tensile strength, and is cheaper than many other elastomers.

Cons of Buna-N

Cons of Buna-N

While this rubber has many strengths, it also has its weak points. Buna-N is susceptive to ozone, ketones, ethers, esters, aromatic hydrocarbons, automotive brake fluid, strong acids, and aldehydes. It also has poor resistance to fire, sunlight, harsh weather, and high temperatures. Additionally, products with Buna-N, such as non-latex gloves, can oxidize if in contact with strong oxidizers. It is also less flexible than other rubbers. The more acrylonitrile in Buna-N, the less flexible it becomes.

In conclusion, is Buna-N (NBR) Right for You?

In conclusion, is Buna-N (NBR) Right for You?

Buna-N is a highly versatile and customizable rubber that can be used for many applications, including automotive, marine, and aeronautical fuel and oil systems.

SUNLED manufactures hundreds of standard and custom-made sealing products based on NBR compound. If you’re interested in learning more about the material and how it can be customized for your specific needs, PLEASE CONTACT US VIA kent.wei@isunled.com. We’d be happy to help!

Send Email

Send Email